Lean supply chain experience

|

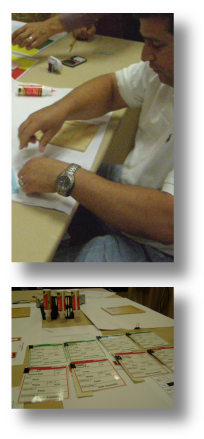

Looking to find system wide improvement in your Performance Chain? During this 1-day simulation-based lab, everyone in the room becomes part of a global Performance Chain, working from the moment demand is triggered until value is delivered to customers. Participants see, map and measure flow of products and its impact on business and financial performance.

In a 4-round simulation and active exchange over results, we:

- Find the constraints to healthy flow of products through the Performance Chain

- Assess iterative changes on capacity, flow, planning systems and capability to solve dynamic customer needs

- Use actual results from each simulation round to prioritize and decide what to change with the goal of increasing performance

- Apply a repeatable approach to transform both the flow of products and the way people work together to make improvements sustainable

What is it?

- A 1-day simulation-based lab where participants experience how demand become output and then cash in a global Performance Chain

- Over four iterative rounds, contraints are broken and dynamic customer demands are met

- Participants apply repeatable techniques to see, map, change and measure performance

Who is it for?

- Any product or manufacturing, fulfillment or assembly organization

- Managers, directors and business unit leadership teams

- Manufacturing, engineering, planning, finance or supply chain departments or business groups

What you get:

- Participants see a Performance Chain above departmental silos and issues that constrain the performance of the system

- How to accelerate flow and to free working capital

- How to embed sustainability in processes and in how people work together to achieve positive change